Plastic recycling has become a critical component in addressing the mounting environmental challenge of global plastic waste. Among advanced recycling methodologies, pyrolysis stands out for its ability to convert diverse plastic streams into valuable fuel products. Energy-efficient pyrolysis plant design not only maximizes output but also minimizes operational costs and environmental footprint, offering a pragmatic solution for sustainable waste management.

Optimizing Reactor Configuration

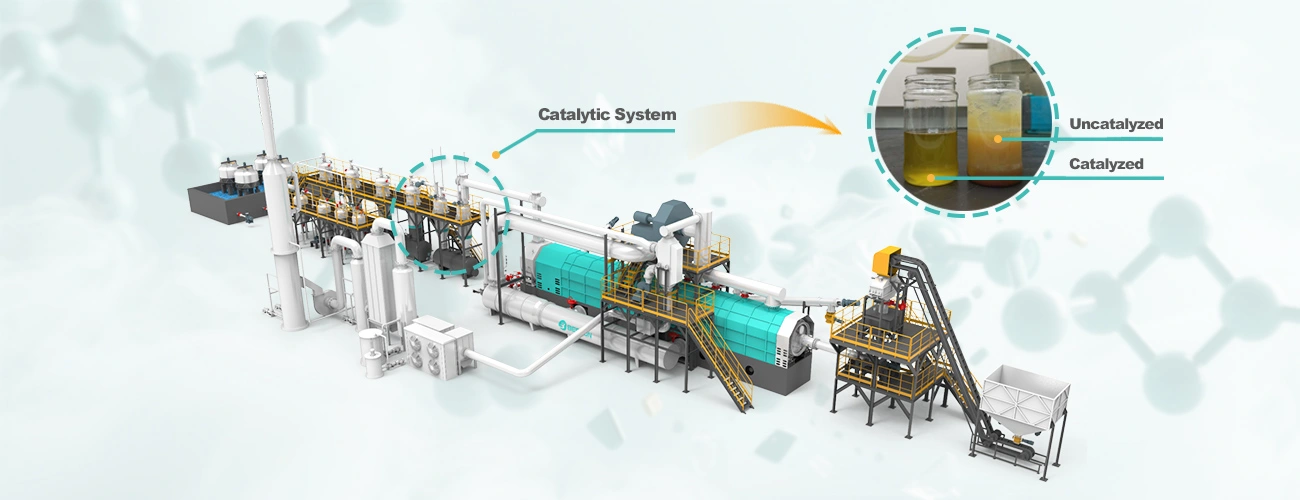

The core of any plastic pyrolysis equipment is the reactor, where thermal decomposition of polymers occurs under controlled conditions. A well-designed reactor ensures uniform heat distribution, preventing local overheating and incomplete conversion. Employing a continuous feeding system with precise temperature control enhances the overall energy efficiency of the process. Modern designs often integrate multi-stage heating zones, which allow for gradual depolymerization and maximize liquid fuel yield. In regions such as Nigeria, demand for reliable pyrolysis plant in Nigeria has surged, driven by both industrial and community-level waste management needs.

Heat Recovery and Insulation Strategies

Energy conservation in a waste plastic to oil machine is heavily influenced by heat retention and recovery systems. High-quality refractory linings reduce thermal losses, while heat exchangers can reclaim residual energy from exhaust gases. This recovered heat can preheat incoming feedstock or maintain reactor temperature, reducing fuel consumption and increasing operational efficiency. Effective insulation and energy recovery are pivotal in achieving low operational costs and improving the sustainability profile of a plastic to fuel machine for sale.

Feedstock Versatility and Pretreatment

Energy-efficient pyrolysis plant must accommodate heterogeneous plastic waste streams, including polyethylene, polypropylene, and polystyrene. Pretreatment techniques such as shredding, drying, and contaminant removal optimize feedstock consistency, which directly impacts thermal efficiency and product quality. Uniform particle size promotes even heat penetration, reducing the energy required for pyrolysis while enhancing the yield of high-value liquid oil. For investors seeking pyrolysis plant in Nigeria, feedstock flexibility is a critical factor in securing continuous and reliable production.

Integrated Condensation and Product Separation

Post-pyrolysis, the design of condensation and separation systems determines the recovery rate of oil, gas, and solid residues. Multi-stage condensation units coupled with efficient gas recycling loops not only maximize liquid fuel output but also reduce emissions. Solid char residues can be repurposed as an energy source or further processed, contributing to a circular economy. The integration of advanced separation technologies is essential for energy-efficient operations and ensuring compliance with environmental standards.

Automation and Process Control

Automation in modern waste plastic to oil machine allows for real-time monitoring of temperature, pressure, and feed rate. Advanced control systems optimize thermal profiles and reactor conditions, minimizing human intervention and energy wastage. Intelligent automation enhances plant reliability, reduces downtime, and ensures consistent quality of produced oil. Companies offering plastic to fuel machine for sale increasingly highlight these features to attract industrial clients and sustainable initiatives in markets such as Nigeria.

Conclusion

Designing an energy-efficient pyrolysis plant requires a comprehensive approach that balances reactor engineering, heat recovery, feedstock management, and process automation. Incorporating these elements into a plastic pyrolysis equipment framework not only increases operational efficiency but also strengthens economic viability and environmental stewardship. As waste plastic volumes continue to rise, investing in sophisticated waste plastic to oil machine solutions is becoming an essential strategy for sustainable resource management globally.