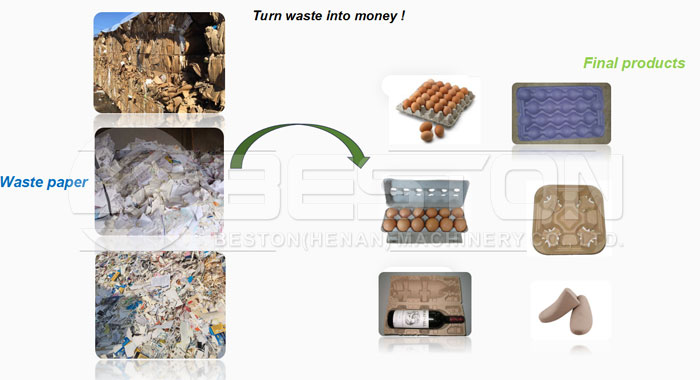

From a simple point of view, the egg tray making machine has been very effective and efficient for the recycling industry. Thus far it has made the best use of waste paper all around the globe. If you didn’t already know, waste paper is a serious issue for many countries all around the globe. Read on as we dive into the egg tray making machine.

These state-of-the-art machines are graciously priced for as little as 9000 USD but can cost as much as 70000 USD depending on the specs. Leading manufacturer Beston (Ведущий производитель Beston) has done its best to answer some of the most complex questions over time. The egg tray making machine ensures that reusing waste paper brings significant profits since investors can easily manufacture egg trays from waste paper, old cartons, and even newspapers.

In addition, the egg tray maker is very simple and easy to use with a little bit of training. The first main system of the egg tray making machine is the pulping system. The pulping system (Система варки целлюлозы) uses a hydraulic pulper and includes the following:

* Stirred tank

* Pulp pond beater

* Water pool

* Pulp pool

The egg tray making machine was designed to automatically integrate the pulping system to reduce the initial labor cost. This in turn also reduces the floor space and the efficiency of the pulping system. Another major system of the egg tray machine is the forming system.

The forming system contains a vacuum pump, the molding machine, the water pump, and an air compressor. The main and most important part of the machine is the molding machine. This section is used to transfer and form the mold. Customers can select between either plastic or metal molds if they prefer.

When compared to the plastic molds, aluminum molds are more durable but expensive. In essence, it even produces higher quality trays than plastic molds. Additionally, because of the variation in egg sizes, the machine manufacturer is able to easily customize to suit the needs of each individual customers.

The last main system of the egg tray making machine is the drying system. When the trays have been molded, they need to be dried before they can be packed. Depending on the daily capacity, customers are given a choice between four drying systems. These include the following:

* Brick drying with carts

* Drying in the sun

* Metal drying

* Conveying drying system

It should be noted that different systems have different effects and the rate at which they dry are different. Hence, customers are advised to select based on their needs such as production rate, climate, space, and budget.

As we conclude we have just looked at the egg tray making machine. The egg tray making machine is a state-of-the-art machine that was designed with pollution in mind. These machines do a great service to humanity and other living animals since they reduce paper waste all around the globe. So if you’re interested in making a meaningful investment, the egg tray making machine is perfect for you.