Just about everyone knows that tires do not break down easily, and more and more waste tires are filling up the landfills across the globe. The methods to recycle waste tires in a beneficial and green method is not only challenging but was once a business risk for those who were trying to benefit from these methods. However, today there are a number of reliable waste tire recycling plant that offer lucrative business opportunities to turn waste tires into fuel oil.

The tire recycling machine disposes of waste tires while generating combustible gas, black steel, and fuel oil. Each of these end products is valuable and can be sold and used again. Here is a list of some of the applications associated with these end products:

Fuel Oil

– Is easy to sell directly

– This fuel is useful in facilities such as cement factories, restaurants, power plants and more

– The fuel oil can also be reprocessed into gasoline or diesel through an oil-distillation machine

Carbon Black

– Another end product that is sold directly

– This end product is reprocessed into a high-quality carbon with the use of carbon-black grinding equipment

– This end product is also used to make carbon bricks using briquette equipment. Click here to know more about Beston Machinery.

Steel Wire

– Can be sold direct

Combustible Gas

– This gas is used as a fuel to reheat the reactor

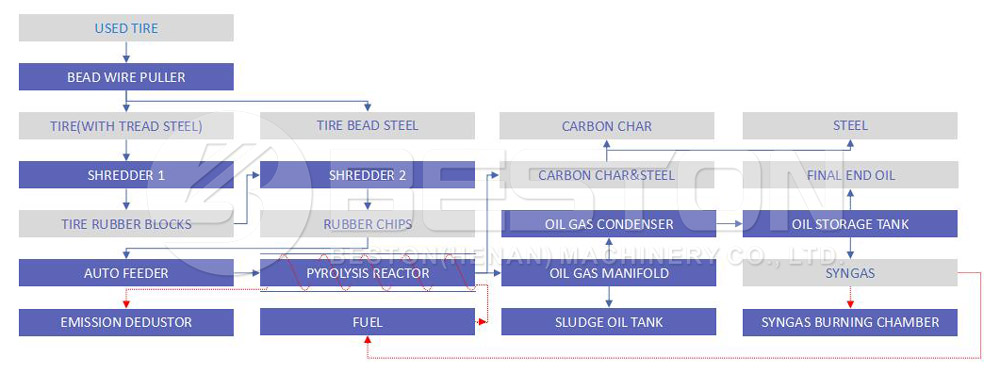

The Working Process Of The Tire Recycling Machine

The first step involves preparing the waste tires into an appropriate size. For whole tires, the steel wires need to be removed from the sidewalls. The tires are then cut into diameters of 1200mm. The pieces are then crushed into smaller pieces of around 2 to 5mm using the shredder.

The second step involves feeding the shredded tires automatically or manually into the reactor. The burning room sends hot air into the reactor to heat it up. Once the temperature reaches 100 degrees, oil gas is generated and flows into the manifold.

In the manifold, the heavy particles will liquefy into a heavy oil where it drops into the heavy-oil tank. The light oil gases will rise up and flow into the condenser.

From here the oil gases will liquefy into a fuel oil before it flows into a tank. Inside the hydro-seal, combustible gases will be cleansed and desulfurized. This gas is then recycled and sent into the burning room where it provides heat. Get waste tyre pyrolysis plant cost here.

The next step involves a heat-exchange process. The hot smoke leaves the reactor into the inner pipes of the heat-exchange system. Oxygen then leaves through a pipe in this heat-exchange system. Through this process, the air heats up from the hot smoke where it is transferred into the burning-room which provides more oxygen.

The next step involves the process of smoke treatment. Inside the flue-condenser, the smoke starts to cool down where it then flows into a dedusting system. The smoke then goes through water spraying and washing, a ceramic-ring absorption along with activated-carbon absorption. After the smoke has gone through 4 filters, the smoke is clean and matches up to the laws from the EU environmental protection about emissions.

From here steel wire and carbon black are discharged by the auto-screw discharger. The magnetic separator is used to separate the carbon black and the steel wires where the end products are sent into a storage tank. Get high quality tyre to oil plant here.